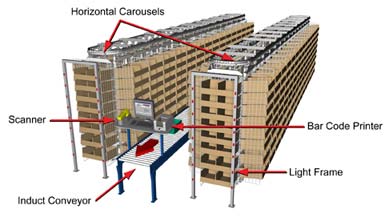

Horizontal Carousels

Horizontal carousels consist of an oval track with rotating bins containing shelves that deliver items to the operator. Often used in integrated workstations of carousels called a "pod." This allows an operator to pick from one active carousel while the others are pre-positioning to be picked the moment the operator is ready.

Horizontal carousels consist of an oval track with rotating bins containing shelves that deliver items to the operator. Often used in integrated workstations of carousels called a "pod." This allows an operator to pick from one active carousel while the others are pre-positioning to be picked the moment the operator is ready.

Every carousel uses one of the many integrated QuickPick® pick-to-light technologies to indicate the active carousel, shelf level and quantity of items to pick, making batch picking simple, fast and easy.

What makes the horizontal carousel the best?

- Increased throughput up to 600%

- Reduced floor space requirements up to 60%

- Flexible design provides instantly adjustable shelf levels

- Reduced labor up to 2/3

- Move and change workstation designs easily

- Workstation design that is easily modified Increased level of accuracy up to 99.9% levels

- The ability to increase or decrease a carousel's length easily

- Extended order cut-off times

- Fast ROI (Return On Investment)

Applications

From stand-alone workstations to fully integrated systems, our horizontal carousels are the right choice for order picking, buffering, consolidation, kitting, work-in-progress, and stock room applications for distribution, manufacturing, retail and warehouses. Ideal for meeting cost effective split case picking, consolidation, sortation and case handling requirements.

Automated pick-to-light carousel systems bring the items to the operator eliminating wasted walk and search time. Provides pick-to-light accuracy on "EVERY SKU" without the additional cost, floor space and labor associated with traditional pick-to-light shelving systems and converts slow and medium movers into profit.

Bins are available with 3" adjustable shelving, hopper bins, cantilever bins to store totes, containers, cases, cartons and specialty holders to meet virtually any requirement. Mix and match per bin or carousel for maximum flexibility.

|