|

This global manufacturer is known for fusing the influences of sport, lifestyle and fashion through technical innovation and revolutionary design to deliver the unexpected in sportlifestyle footwear, apparel and accessories.

Their distribution facility, which works in partnership with them to distribute their apparel throughout the United States and Puerto Rico, needed help with it's logistics management operation. The operation at this facility centers completely around the receiving, storing, order processing and shipping of all apparel.

Logistics Management

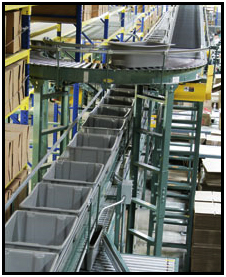

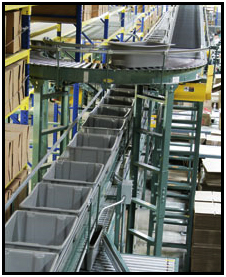

Upon receiving items, the conveyor system transports boxes of apparel in totes to a pick module (replenishment) where the apparel is stored in specific locations for picking. The conveyor system also transports empty totes to a pick module where apparel is picked and placed into the totes. Totes are then moved either to the VAS (Value Added Service) area, packing, a "hospital" and "no read" line, or are recirculated through the pick module. After arriving at the packing area, the totes are manually removed from the conveyor and the contents packed into shipping cartons.

The packed shipping cartons are manually placed onto a take away conveyor and moved across an inline scale to either a UPS shipping conveyor or a consolidation loop. The remaining empty totes in packing are also manually placed onto the same take away conveyor where they move toward the inline scale. They are automatically diverted by a pop-up transfer onto the empty tote line.

The system, as designed by a Hytrol Integration Partner, was designed to enable the company to change the speed of the equipment to accommodate throughput. Adjustments were made after installation to keep pace with customer needs. Currently, the system handles between 20 and 25 thousand pieces a shift, with a goal of 40 thousand. In addition to basic receiving, stocking, picking, and shipping, the center also has the capability of handling value-added services such as "hang-tags," custom bagging, pricing, and other customer requirements. Hytrol conveyors are also used to help with these services.

|