|

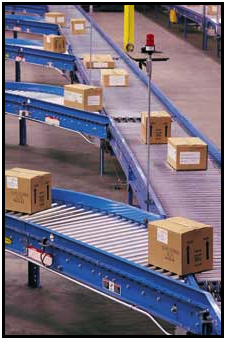

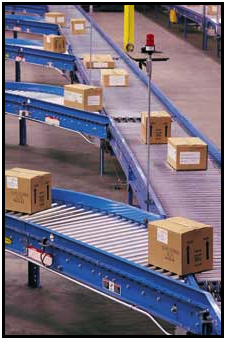

Two years ago, this home goods manufacturer was picking orders onto pallets one store at a time. Things have changed dramatically since then. The company is now processing more orders, more efficiently with only one third of the staff. The difference: a new distribution center with a streamlined and efficient conveyor system.

The Manual Approach Just Wasn't Cutting It

Between retail, wholesale, catalog and online orders this producer of candles and home decor items experienced some unique challenges with each of its distribution channels. The challenges become particularly tough when the business is growing. And their business has been growing at a rapid rate ever since the company was founded just over four years ago. Between retail, wholesale, catalog and online orders this producer of candles and home decor items experienced some unique challenges with each of its distribution channels. The challenges become particularly tough when the business is growing. And their business has been growing at a rapid rate ever since the company was founded just over four years ago.

The order fulfillment challenges were especially evident at the company's existing warehouse. That facility handled product distribution for the company's retail, catalog, and Web orders. Other facilities take care of the wholesale operations.

Order processing at the old warehouse had been entirely manual�an approach not particularly supportive of business growth. "When I started here over two years ago, we were picking orders onto pallets," recalls the company's vice president of logistics. "We had no conveyor capabilities whatsoever. We were picking one store at a time, one SKU at a time."

The opportunity for change came when they acquired a new complex that had existing racks and shelving in place. The company worked hand-in-hand with a Hytrol Integration Partner to design a conveyor system that would capitalize on the existing equipment in place and deliver the kind of productivity needed to support growing business lines.

A New System - On Time & On Budget

The new installation has had an immediate and positive impact on the company's distribution operations. Whereas in the past, orders were picked one store at a time, They now can do a much more efficient bulk distribution pick. "We can pick orders in bulk for a dozen stores at a time and then sort to the appropriate stores. This is a direct result of the Hytrol conveyor system." The new installation has had an immediate and positive impact on the company's distribution operations. Whereas in the past, orders were picked one store at a time, They now can do a much more efficient bulk distribution pick. "We can pick orders in bulk for a dozen stores at a time and then sort to the appropriate stores. This is a direct result of the Hytrol conveyor system."

There were other benefits as well. "The system was implemented on time, on budget without one hitch," says the logistics V.P. "A lot of credit goes to our Hytrol Integration Partner who helped us design and implement the system."

While everything has worked out well to date, management is looking forward to the upcoming peak shipping months of November and December. "We expect fabulous results in the busy season." (noting that order volume can increase by a factor of four during this period) "We'll be able to get as much done in a 12-hour shift as what used to take us 36 to 48 hours.

|

Between retail, wholesale, catalog and online orders this producer of candles and home decor items experienced some unique challenges with each of its distribution channels. The challenges become particularly tough when the business is growing. And their business has been growing at a rapid rate ever since the company was founded just over four years ago.

Between retail, wholesale, catalog and online orders this producer of candles and home decor items experienced some unique challenges with each of its distribution channels. The challenges become particularly tough when the business is growing. And their business has been growing at a rapid rate ever since the company was founded just over four years ago. The new installation has had an immediate and positive impact on the company's distribution operations. Whereas in the past, orders were picked one store at a time, They now can do a much more efficient bulk distribution pick. "We can pick orders in bulk for a dozen stores at a time and then sort to the appropriate stores. This is a direct result of the Hytrol conveyor system."

The new installation has had an immediate and positive impact on the company's distribution operations. Whereas in the past, orders were picked one store at a time, They now can do a much more efficient bulk distribution pick. "We can pick orders in bulk for a dozen stores at a time and then sort to the appropriate stores. This is a direct result of the Hytrol conveyor system."